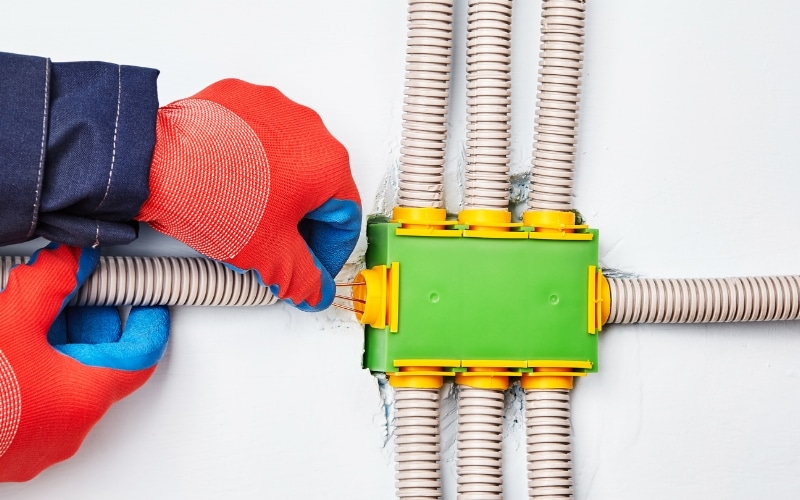

Conduits are an important part of a building project that protects the electrical wires within a structure. This piping system protects your cables from deadly collisions and vapor exposure.

Conduit is also a route for either energy or transmission electrical wiring. There are different types of conduits you can use for other areas of a building.

However, you might wonder if using a conduit on drywall is possible.

Conduit will surely pass through drywall since you can use them for either invisible or uncovered applications. However, conduit varies in thickness and type, so install the best one for your wall.

This article will explain everything you need to know about running a conduit through drywall, from the code guiding the installation to the steps you need to take to install them on drywall.

Ready for a Drywall Quiz?

Can You Run Conduit Through Drywall?

You can run an electric conduit through your drywall and other places such as data centers, underpasses, ports, and bridges. However, wet or dangerous places require a special conduit.

Here are some reasons for installing a conduit system.

- Conduit gives cavities, mainly for producing faucets and splices in conductors.

- You can use them as pull outlets for the conductors installed.

- Also, conduit systems can strongly attach conduit divisions.

- You can use them as taps for branch conduit runs.

- It gives conductors access to future maintenance systems.

- It allows conduit runs to bend up to 90°.

- You can use it as a fixing platform for lighting and wiring appliances.

You can distinguish the conduit system through the wall density, mechanical stiffness, and tubing equipment.

What Does the Code Say About Conduit Through Drywall?

It’s legal to use conduits for both concealed and exposed areas. Therefore you are free to use a conduit on your drywall.

However, according to the National Electrical Code, installing a rigid conduit the code approves across the wall is the best way to protect an exposed cable.

Then fix an individual conductor cable in the conduit. Doing so will protect your wall against damage.

However, you cannot just use conductor cables with an electric cable. Instead, it has an exact cable you can use. The common ones are the THHN cables.

They are individual copper wires that conduct electricity and have flexible insulation that is color-coded and resistant to heat.

According to the National electrical code, a regulation guides a specific number of cables that different sizes of conduit must contain.

Here are some of the regulations;

- A conduit whose size is half an inch can contain up to nine of the 12-gauge cables. This half-inch conduit can also contain about 12 of the 14-gauge cords.

- A conduit of about ¾ inch must not contain more than 16 of a 12-gauge cable. Also, this conduit must not contain more than 22 of a 14-gauge wire.

Not all electricians can install non-metallic cables. Hence, it’s best to use only THHN conductors or other approved cables in the conduit since they are cheap and easy to install.

How Do You Run Conduit Through Drywall?

Installing a conduit on drywall is tricky. So it’s best to leave the installation to a professional and if you still need to, ensure you have the guidance of an expert.

Before you lay your hands on anything, you must gather the necessary tools.

Here are some of the tools you need.

- Non-contact voltage tester

- Stud finder

- Wires (non-metallic sheathed wires)

- Cord connectors

- Drywall anchors

- Hammer

- Drill

- Wire blade

- Utility knife

- Cable nuts

- A wire-pulling tool

When you have your tool ready, you can start the installation process. Just follow the guide below.

Step 1:

The first step for installation is to study the conduit plan. It’s best to review the plan to know if you want to make any alterations.

Step 2:

The second step is to switch off the circuit light. Once you switch it off, check if the circuit is off using a voltage tester.

If not, continue switching off the circuit breaker until there is no more circuit.

Step 3:

Once you confirm that there is no more power, you can remove the junction box cover and fix a wire connection for the new connection.

It’s best to also fix a cord connector to the toolbox to which the new cable will connect.

Step 4:

With the help of a stud finder, mark all wall studs between the junction and the toolbox. And if you have any adjustments, this is the best time to do them.

Step 5:

Make a hole on the wall where you will put the conduit, and ensure the hole is big and the conduit can fit through.

Also, making an extra hole for easy access is best, so the conduit can leave or enter the wall again.

Step 6:

The next step is to cut the conduit into the right sizes. If you are using a flexible conduit, you are good. However, if your conduit is rigid, you can shape it with a bender.

Step 7:

Inspect the hole and ensure the shaped conduit can fit. If not, widen it till it fits. Again, make sure there is no water in the hole that can affect the conduit.

Step 8:

After verifying the hole, put it in the conduit. You can use a puller to draw in 90° bends.

Step 9:

When you are through sliding in the conduit, introduce supports. Let the first hanger be about three feet from the junction box, and the next one be about 10 feet.

Then use a drywall anchor to attach the conduit hanger.

Step 10:

Then draw the wire through the conduit. If you have a straight conduit, use a string or fishing weight procedure to draw out your wire.

However, use a fish tape method if it’s an angled or curved conduit. Different methods exist to pull a wire through conduit; pick what is best for you.

Step 11:

Cut the wire to prolong at least eight inches from the junction and device box. Use a utility to strip the wire and hold each end with the attaching wires at each box.

Then complete the connection with a cable nut. You can now place the junction and device box covers and switch on the circuit breaker to test the connection.

Step 12:

Once your connection is perfect, use silicone caulk to close the gap between the conduit and your drywall.

How to Rewire a House With Drywall?

Rewiring a house with drywall may seem impossible. But it is possible with the least disturbance.

Here are four steps to rewire a house without removing the drywall.

#1. Planning Phase

When you want to rewire your house, you need to plan where and how you will propel each circuit so that your drywall will be intact and reduce disorder.

This plan includes the following:

- It contains a comprehensive plan explaining the old circuit routes.

- It consists of a comprehensive plan of where the new circuit will pass. If the old route is not visible or you want to add new needs.

- Cable calculations- number of cables and the best paths for the new circuit.

#2. Preparation Stage

Since you want to rewire the drywall, you must run the cables through the attic or crawl space. It would help if you prepared the areas the cables will pass through.

Also, this stage will help you know what to remove to have a clear path. And remember the clutter beside the electrical outlet. Doing all this will make the electrician’s work easier.

#3. Removal Stage

This stage requires you to remove all the old circuits. This stage is very tricky for two reasons.

- The wires are something you cannot easily draw out.

- You need to recycle old wires, so you can’t just trash them.

So it would be best if you waited for the electrician to cut all the old wires. Then, remove the sites from the room if you can repair your drywall.

But if you don’t want to, remove it through the crawl space. So the electrician will tape the new wire to the old one so that once you have the old one out, the new one will take its place.

#4. Putting the New Wires

The rewiring process is a tasking process. Before running a new wire, the electrician must:

- Cut an opening for each circuit toolbox.

- He will drill a hole of about ¾ inch at the top, bottom, or under each opening.

So if you get all the stages right, your new cable will be in the correct outlet on the drywall.

Is Surface Wiring Better Than Conduit on Drywall?

Although conduit is more expensive, it is safer than surface wiring, making it better.

The table below shows the difference between these two wiring systems.

| Surface Wiring | Conduit Wiring |

|---|---|

| The surface wiring runs on the surface. | The installation of the conduit is inside the wall. |

| It causes sparks, often making it less safe. | It provides safety for residents since there is lesser contact. |

| The wiring looks rough and scattered. | The arrangement is neat, and the wires are invisible. |

So it’s best to go for conduit than surface wiring since it has more safety measures.