Wood is the commonest material for roofs and other indoor and outdoor structures.

They are less durable than metals but pose some characteristics which make them ideal for roofing.

The durability of a roof depends on the wood used for it. The wood type also determines the susceptibility of roofs and other structures to insect attacks and other defects.

Pressure-treated wood and Douglas fir wood are both great for structures. So, which of them is better?

Pressure-treated wood is very durable because of the chemical treatment it has undergone. On the other hand, Douglas fir wood is naturally strong and may not require treatment to make it last longer. Both are preferable to the other in different situations.

This article will acquaint you with pressure-treated and Douglas fir wood and compare the two. The information here will enable you to choose the better wood for your roof.

Ready for a Roofing Quiz?

What Is Pressure-Treated Wood?

Some woods undergo special treatment with preservatives. Woods of this sort are resistant to rot and insect attacks because of the chemicals introduced into them.

These kinds of lumber are known as pressure-treated wood.

Pressure-treated woods also have fire-resistant properties courtesy of fire retardants in them.

They char quickly in the event of a fire, producing less smoke and flame. Pressure-treating wood involves forcing preservatives deep into it for retention.

This process entails the following steps:

- Ordering and shipping wood to the treatment plant.

- Checking the wood’s moisture content.

- Please place it in the vacuum pressure vessel and seal the cylinder.

- Removal of air from the wood and cylinder using an industrial vacuum pump.

- Flooding of the cylinder with preservative solution.

- Application of pressure to force the chemical into the wood.

- Adjustment of pressure settings and cycle times. These settings depend on desired retention level and wood species under treatment.

- Drainage of the cylinder and removal of excess solution from the wood.

- Remove the wood from the cylinder and place it on a drip pad.

- Tagging of the wood.

Micronized Copper Quaternary (MCQ), Sodium Borate, Copper azole, and Alkaline Copper Quaternary (ACQ) are common chemicals for making pressure-treated wood.

Formerly, chromate copper arsenate was in wide use for the process. Presently, there are restrictions on its application due to health concerns.

Pressure-treated woods are ideal for use in many outdoor projects. These applications include decks, fences, wooden sidewalks, and structures exposed to moisture.

There are also different pressure-treated wood sizes available for different outdoor projects. These woods are more advantageous than natural woods in many ways.

However, they have their downsides too. The table below shows the pros and cons of pressure-treated woods:

| Pros | Cons |

|---|---|

| Pressure-treated woods are versatile. | They pose health concerns to people. |

| They are durable. | They are susceptible to splintering and checking. |

| Ease of repair. | High maintenance. |

| They repel insect attacks and rot. | They fade easily. |

What Is Douglas Fir?

Douglas fir is wood from the evergreen coniferous Douglas fir tree (Pseudotsuga menziesii) native to western North America.

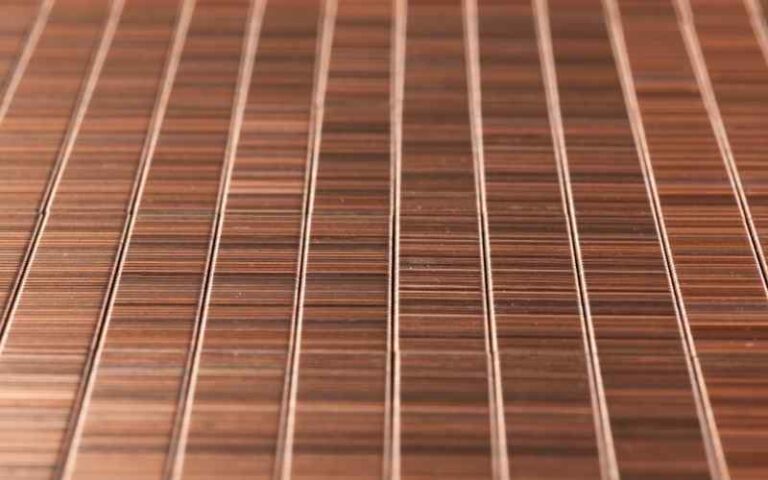

Douglas fir usually appears light brown with darker growth rings. However, the color of the wood varies depending on the tree’s location and age.

Its grain is generally straight but can be slightly wavy. It has a moderate luster and a fine to medium texture.

The wood also gives off a resinous odor when working on it. Douglas fir is considerably stiff and ranks among the heaviest and hardest softwoods.

It is moderately durable and resistant to rot. However, it is susceptible to insect attack.

This wood is also resistant to abrasion due to its hardness. Hence, it is suitable for application in areas where wearing is inevitable.

The primary use of Douglas fir wood is in building and construction.

The reason for this is its strength which makes it fit for heavy structural applications like roof trusses and glulam beams.

You can also make doors and sashes out of Douglas fir because of its high quality.

The wood is also capable of marine pilings, furniture, veneers, cabinets, ships and boats, and general millwork.

Douglas fir has relatively easy workability and good machining attributes. Stains, glues, and finishes work on it well. You can also sand it to a smooth finish.

Though moderately, the Douglas fir wood also has blunting effects on cutters. However, it has a good ability to hold screws and nails.

Preservation limits the natural weakness of Douglas fir and increases its strength.

Methods like kiln drying and pressure treatment are the commonest for preserving this wood.

Which Wood Is Best For Roofing; Pressure Treated or Douglas Fir?

There are many factors one must consider to make the best choice of wood for roofing.

Pressure-treated wood and Douglas fir are both great for roofing. Hence, it is a little difficult to choose one of them for roofing purposes.

However, comparing both in terms of roofing attributes can help decide which one is best for roofing.

Let’s take a look at their differences in these qualities.

#1. Durability

Durability is an extremely important factor when selecting wood for roofing. Wood meant for the roof must be strong and able to last long to avoid falling off.

By treatment, pressure-treated woods are more durable than natural Douglas fir.

#2. Moisture and Insect Resistance

Moisture and insects pose significant threats to roofing wood in many areas.

Hence, wood intended for roofing must possess some form of resistance to these elements.

The Douglas fir and pressure-treated wood are somewhat resistant to moisture and insects.

However, the opposition of the latter wood is greater than that of the former.

#3. Cost

It is good to use quality wood for roofing purposes. Nevertheless, expensive lumber can be a constraint to roofing despite its quality.

The Douglas fir and pressure-treated are both expensive. However, natural Douglas fir is less expensive and readily available than its pressure-treated counterpart.

Hence, the Douglas fir is ideal if you want to save on good quality wood for roofing.

#4. Safety

Safety is crucial during roofing. The state of the wood intended for this purpose plays a part in determining how secure the worker is.

Douglas fir is significantly safer to work with than pressure-treated wood. The reason for this is pretty obvious.

Pressure-treated wood contains chemicals that might pose health concerns.

Furthermore, the chemicals used for treating the wood might react with galvanized roofing sheets.

This interaction may result in damage to the sheets. Generally, Douglas fir is good for roofing, but pressure-treated wood will serve better.

Is Douglas Fir Good For Outdoor Use?

No doubt, Douglas fir is good for outdoor use. It is one of the softwoods suited for external structures and furniture applications.

The wood’s durability and dimensional stability are why you can use it for outdoor purposes.

It can withstand moisture and other elements for a considerable period. It evenly expands and contracts in response to contact with moisture.

Its likelihood to warp and buckle is very rare, especially the ones with clear vertical grains.

Also, Douglas fir can resist rot and weather. It is also resistant to insect attack to an extent. These features primarily define a wood’s suitability for outdoor use.

Furthermore, this wood has beautiful grain patterns, making its products eye-catching. With the best finishing, Douglas fir can give your outdoor structures an aesthetic appeal.

Douglas fir is also very versatile when it comes to outdoor applications. You can use it for porch decking, patios, gazebos, and virtually any furniture for outdoor entertainment.

Despite the Douglas fir’s all-around adaptability for outdoor use, it also has demerits associated with this application area.

Douglas fir is a tough and durable wood. However, it is still softwood. This inherent attribute makes it susceptible to dents on the edges.

Also, Douglas fir is not resistant to sunlight. It can undergo color change drastically on exposure to extreme sunlight.

Douglas fir is resistant to moisture but not entirely waterproof. Constant exposure to moisture and humidity will lead to its deterioration over time.

Summarily, the advantages of Douglas fir in outdoor applications outweigh the disadvantages.

One can even manage these downsides with proper careful handling and proper treatment.

So, if you want your outdoor structure or furniture made of Douglas fir, you can have it. It is okay and will last for years, especially if treated.

Is Douglas Fir More Durable Than Pressure-Treated Wood?

Douglas fir is less durable than pressure-treated wood. Pressure-treated woods have undergone treatments with chemicals that make them outlast natural Douglas fir.

Douglas fir, without treatment, can last 10 to 15 years. Pressure-treated woods, on the other hand, can last up to 20 years and more.

However, it is important to note that Douglas fir is a type of wood, while pressure-treated is a form of wood.

You can also cure Douglas fir to make it last as long as any other pressure-treated wood.

Final Thoughts

The Douglas fir and pressure-treated woods are of great quality for various purposes. However, they are areas where they supersede each other in terms of roofing qualities.

While pressure-treated wood is better suited for roofing, Douglas fir can be equally amazing for the same purpose.