The roof is one part of the building that is essential because it makes living indoors comfortable. In addition, roofs have materials apart from shingles that contribute to their protection.

That’s why adding another layer under the roof shingles is essential. Now, this is where the roofing felt comes in, but can roofing felt serve as a vapor barrier?.

You can use roofing felt as a vapor barrier, but it’s not fully waterproof. Roofing felt allows moisture from inside the building to pass through but doesn’t allow it from the outside. Like other water-resistant barriers, roofing felt is also made of synthetic materials having a protective coating.

Ready for a Roofing Quiz?

Can You Use Roofing Felt as a Vapor Barrier?

You can use roofing felt as a vapor barrier, with its protective asphalt layer; it can resist water/ moisture.

Although, like some waterproof underlayments, the roofing felt is not fully water-resistant but can absorb moisture.

Roofers use the roofing felt and do not complain of any disappointment.

Roofing felt is a permeable moisture barrier, meaning that it can also allow moisture to pass through.

It provides moisture that accumulates from inside the building and resists any coming from the outside from passing.

Consequently, the water vapor from the steam inside gets to any wooden part of the roof, which can be dangerous.

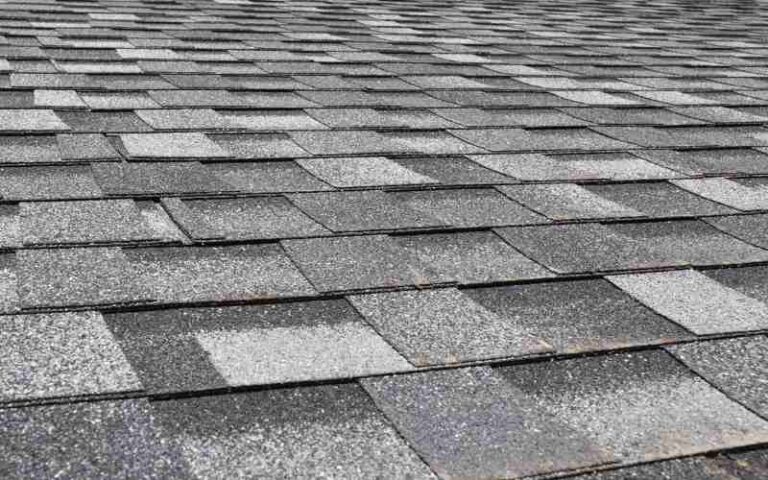

When you see a building, the evident and solid shingles or any roofing material are what one sees as protection. Yes, it’s true, but roofing sheets are not enough protection; that’s why an extra sub-layer is here.

Regardless of the essence of overlapping the shingles, some areas are still open to stable weather conditions taking over.

A shingle is the first protection against harsh weather, but water can find its way through with time. If you have roofing felt installed, that serves as sub protection from water vapor.

Not being strong enough, it’s capable of draining out the water from the building rather than letting water vapor pass through.

The type of roofing felt saturated with asphalt, known as asphalt felt paper, is also water-resistant. This paper is one of the earliest roofs felt that roofers or professionals have been using, and it does the work.

With its asphalt coating, this traditional asphalt felt makes the felt paper made from cellulose material, durable, and water-resistant.

You will also hear of a rubber roofing felt being easy and reliable when using. When applying an underlayment, you need to consider what type of building suits the particular building.

A rubber underlayment mostly goes with flat roof buildings, and others, while roofing felt can go to every kind.

It would be best to consider the weather or the temperate region you reside. Roofing felt are of different weights, 15lbs and 30lbs.

If it’s a hot, humid climate, 15lbs is a good choice, and for a cold environment, 30lbs is good. You can find other higher weights.

That’s why it’s best to contact roofing professionals to check what type and weight of roofing felt to use.

Some hot areas sometimes need no vapor barrier felt, but it’s always advisable to add extra protection. Roofing felt is a sound vapor barrier that’s been in use for many years now.

Many roofers and experts are more conversant with it as one of the best sublayer protection for your roof.

What Can I Use as a Vapor Barrier?

You can use any moisture-resistant sheet material, a material that prevents anything relating to condensation from forming in roofs or walls. Read more to know if Roofing Felt Be Used Under Laminate Flooring?

The primary purpose of a vapor barrier is to make the building last longer, stop mold growth and make it comfortable. A quality of a sound vapor barrier is being able to vary degree in permeability.

When the material changes its permeability, it allows some vapor to pass through it back and forth. Consequently, it prevents water steam from passing through when vapor condenses and allows moisture from inside.

The amount of permeability is in ‘perms,’ which determines the quality of a vapor barrier.

Why would the vapor barrier still allow vapor to pass through, as the name implies? So it is a ‘barrier’?.

The border is against moisture, and if a vapor barrier doesn’t allow vapor to flow, the purpose is entirely lost.

A vapor barrier should prevent water vapor from getting to a building’s roof, ceiling, walls, et cetera.

Without a sound vapor barrier, vapor reaching building parts will encourage mold growth and damage the building’s materials.

You can use a barricade building wrap for walls and other parts to serve as a vapor barrier for your building. It doesn’t kick out the known asphalt felt paper as a good product too, and they are both water-resistant barriers.

When a felt paper and a house wrap are without damage, they will still be suitable vapor barriers.

However, there are many other materials that you can use as vapor barriers specifically.

Below are some of them:

- Aluminum foil.

- Asphalt coated kraft paper.

- Foam board insulation.

- Glass and metal sheets.

- Sheet-type roofing membranes.

- Vapor retarder paints.

- Polyethylene film.

- Insulations (expanded polystyrene).

- Asphalt coated felt.

We can place these vapor barriers are into three classes based on their permeability:

#1. Class 1

These materials have a perm rate less than 0.1, e.g., glass, rubber, aluminum foil, and polyethylene film. As a result, they have the highest vapor resistance.

#2. Class 2

They have a permeability rate of 0.1 to 1.0, e.g., asphalt felt paper, plywood, and insulations.

#3. Class 3

This class has a perm rate from 1.0 to 10, for example, concrete and brick.

You will notice that those materials listed under class two are pretty standard. Any material from 1.0 below is a sound vapor barrier that will last for longer.

What Is The Roof Felt Made Of?

Roof felt is made of synthetic and sometimes natural materials, such as fiberglass fiber or compressed polyesters. What gives it its resistivity is the tar or asphalt added to it.

Traditional asphalt felt material is mainly made from wool, making it one of the earliest types of felt.

But nowadays everything, including building materials, is being improved, succeeding the older ones. But this doesn’t stop the production of such felt.

Many building professionals are more familiar with such roof felt. You can also find some roof felt made of aluminum, and it’s still good enough.

Now let’s look at how the roof felt is made after compressing wool fibers in the factory or fiberglass fiber. The coating is dipped in asphalt/bitumen or tar to make it water-resistant.

You can now guess why roofing is waterproof. Bitumen, tar, and asphalt are products of petroleum.

You may ask if an asphalt felt paper and a felt tar paper are the same!. The answer is yes. The similarity between them is that they are both roofing felt.

And the difference is that you coat one with asphalt and the other with tar.

Tar paper is one popular coating material before asphalt felt, so most people make more references to it. Since asphalt felt paper (also roofing felt) is now used more than tar paper.

However, they both do the same thing.

Conclusion

Apart from its beauty, things like a good roof are essential when building. Adding protection to the roof structure is necessary. Roofing experts advise adding a layer of underlayment.

It makes your roof last longer and gives it value. So, learning more about what the roof is ideal.